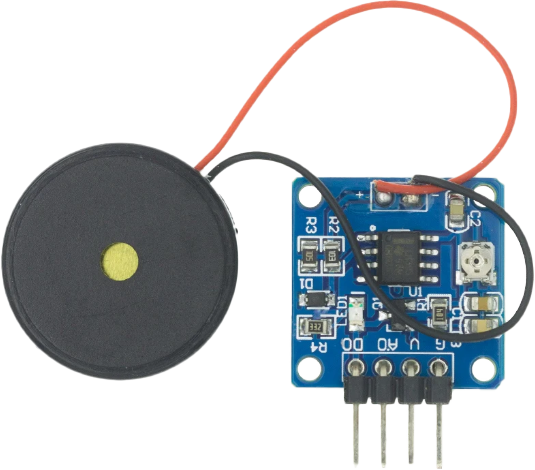

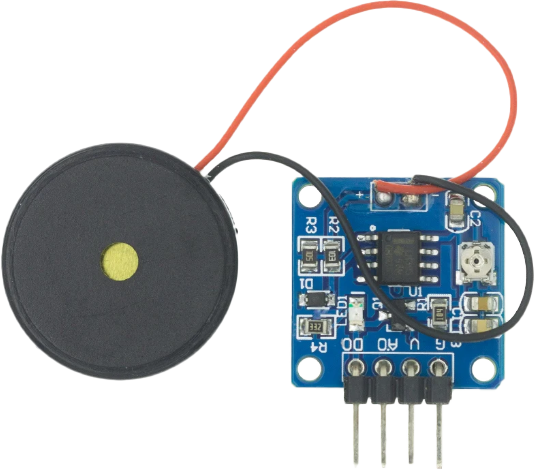

Piezoelectric ceramics are functional ceramic materials that convert mechanical energy and electrical energy. Piezoelectric effect. In addition to piezoelectricity, piezoelectric ceramics have dielectric properties, elasticity, and the like, and have been widely used in medical imaging. Acoustic sensors, acoustic sensors, ultrasonic motors, etc. Piezoelectric ceramics are made by the relative stress of the internal positive and negative charge centers under mechanical stress, which results in opposite bound charges, ie piezoelectric effects, and sensitive properties at both ends of the material. Ceramics are mainly used in the manufacture of ultrasonic transducers, hydroacoustic transducers, electroacoustic transducers, ceramic filters, ceramic transformers, ceramic discriminators, high voltage generators, infrared detectors, surface acoustic wave devices, electro-optic devices, pilot ignition Devices, piezoelectric gyroscope, etc. Product Description: An analogue vibration sensor based on a piezoelectric ceramic sheet is an inverse transformation process that uses piezoelectric ceramics to generate vibration. When the piezoelectric ceramic piece vibrates, an electrical signal is generated. Special sensor expansion boards are used in combination, and analog ports can be weakly perceived. Vibrating electrical signals enable interactive work related to vibration, such as electronic drum interactions. ADO output: The analog voltage ceramic vibration sensor is connected to the UNO controller analog port AO according to the program. When the vibration degree is different, observing the output value of the serial port can realize the vibration-related interaction work. According to the greater the vibration intensity, the higher the output voltage, the sensitivity of the vibration amplitude can be adjusted by the potentiometer. (Low left sensitivity is low. Right turn sensitivity is high.) This product has a high sensitivity and can be adjusted to respond with a mouth blow or a tap with a hand.